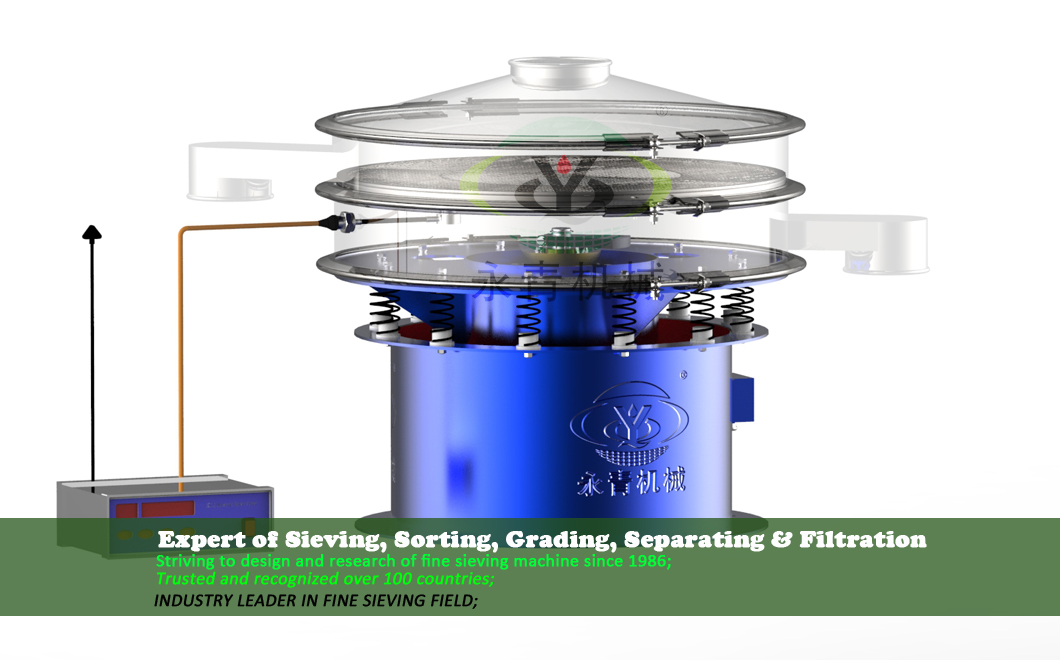

The ultrasonic vibration sieve is a high precision micro powder sieving machine. On the basis of rotary vibration sieve, it is equipped on the net frame directly. The ultrasonic high frequency vibration wave is transmitted to the screen cloth directly. Thus the micro powder can gain large ultrasonic vibration wave, reducing its adhesion, friction, static and wedging in the screen cloth. Then the micro powder screening trouble is successfully solved. The precision and efficiency of screening is improved.

Convert 220V/50HZ or 110V/60HZ power into 18KHz power. The ultrasonic transducer transforms this high frequency power into mechanical vibration of the same frequency. Then the ultrasonic high frequency vibration wave is transmitted to the screen cloth directly to increase the passing rate of material.

Double Vibration Source

The ultrasonic vibration sieve equips two vibrating source—Vibration motor and ultrasonic system. Both of the voltage could be customized according to user’s requirement.

Ultrasonic Frequency Adjustment System

The ultrasonic controlling cabinet can provide 9 kinds of different ultrasonic frequency (C1~C9) with different vibration. The ultrasonic frequency could be freely adjusted without shutting down, based on material characteristics and mesh size of screen cloth.

Lower Working Noise

The ultrasonic is also a whole cleaning device for screen cloth. Without perforated plate and bounce balls, it has no knocking noise in the processing of working.

For a few super micro powder and explosive powder (such as flour, aluminum powder, magnesium powder, sulfur powder, black powder, etc.), during production process, there is a potential safety hazard--- DUST EXPLOSION. So the special explosion-proof motor is well recommended for Explosion-proof application

Parameters

Model | Diameter (mm) | Mesh Area Per Deck (m2) | Number of Decks | Power (KW) | Maximum Size to Process(mm) |

XZS-500 | 500 | 0.14 | 1 | 0.25 | 10 |

XZS-600 | 600 | 0.22 | 1 | 0.25 | 10 |

XZS-800 | 800 | 0.42 | 1 | 0.55 | 10 |

XZS-1000 | 1000 | 0.63 | 1 | 0.75 | 10 |

XZS-1200 | 1200 | 0.95 | 1 | 1.1 | 10 |

XZS-1500 | 1500 | 1.54 | 1 | 1.5 | 10 |

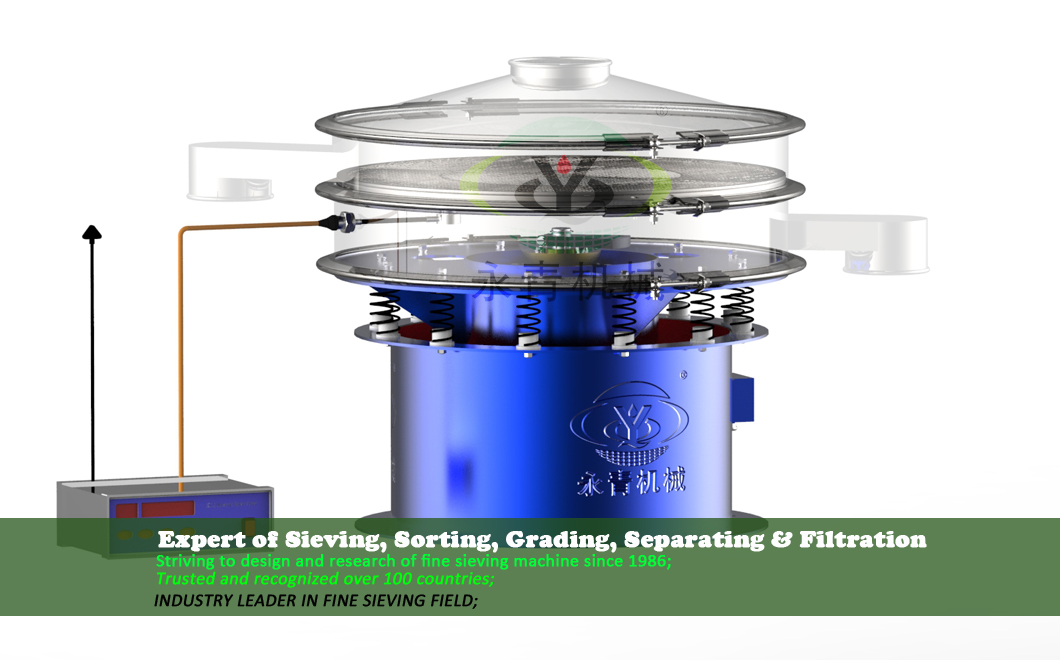

The ultrasonic vibration sieve is a high precision micro powder sieving machine. On the basis of rotary vibration sieve, it is equipped on the net frame directly. The ultrasonic high frequency vibration wave is transmitted to the screen cloth directly. Thus the micro powder can gain large ultrasonic vibration wave, reducing its adhesion, friction, static and wedging in the screen cloth. Then the micro powder screening trouble is successfully solved. The precision and efficiency of screening is improved.

Convert 220V/50HZ or 110V/60HZ power into 18KHz power. The ultrasonic transducer transforms this high frequency power into mechanical vibration of the same frequency. Then the ultrasonic high frequency vibration wave is transmitted to the screen cloth directly to increase the passing rate of material.

Double Vibration Source

The ultrasonic vibration sieve equips two vibrating source—Vibration motor and ultrasonic system. Both of the voltage could be customized according to user’s requirement.

Ultrasonic Frequency Adjustment System

The ultrasonic controlling cabinet can provide 9 kinds of different ultrasonic frequency (C1~C9) with different vibration. The ultrasonic frequency could be freely adjusted without shutting down, based on material characteristics and mesh size of screen cloth.

Lower Working Noise

The ultrasonic is also a whole cleaning device for screen cloth. Without perforated plate and bounce balls, it has no knocking noise in the processing of working.

For a few super micro powder and explosive powder (such as flour, aluminum powder, magnesium powder, sulfur powder, black powder, etc.), during production process, there is a potential safety hazard--- DUST EXPLOSION. So the special explosion-proof motor is well recommended for Explosion-proof application

Parameters

Model | Diameter (mm) | Mesh Area Per Deck (m2) | Number of Decks | Power (KW) | Maximum Size to Process(mm) |

XZS-500 | 500 | 0.14 | 1 | 0.25 | 10 |

XZS-600 | 600 | 0.22 | 1 | 0.25 | 10 |

XZS-800 | 800 | 0.42 | 1 | 0.55 | 10 |

XZS-1000 | 1000 | 0.63 | 1 | 0.75 | 10 |

XZS-1200 | 1200 | 0.95 | 1 | 1.1 | 10 |

XZS-1500 | 1500 | 1.54 | 1 | 1.5 | 10 |

WhatsApp:+86-13598656049

Wechat: +86-13598656049

Skype:yqallenyang

Phone:+86-373-3719492

Tel:+86-13598656049